Define project requirements

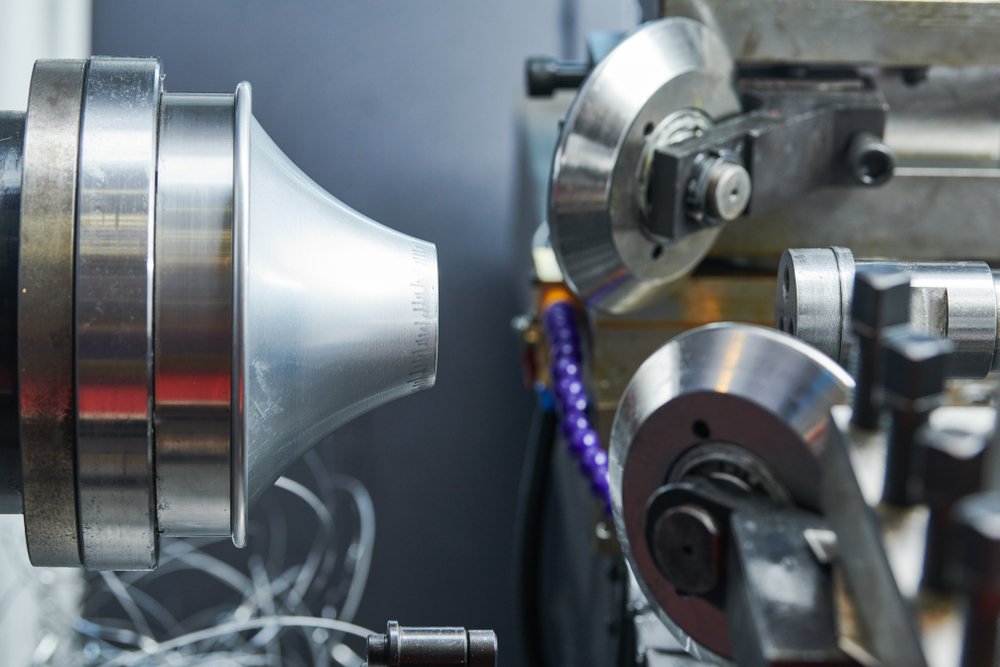

Before deciding on the right metal spinning process, you first need to ensure that the full requirements and scope of the project is clearly laid out. This involves identifying the specifications of the project such as the type of material needed, thickness, dimensions, and tolerances. In addition, you should consider the intended use and any particular performance requirements that might be needed.

For example, if you need dished ends for a pressure vessel, the part will need to be able to withstand very high levels of pressure as well as be strong, corrosion resistant, and long lasting. Therefore, you will need to utilise experienced metal spinners like Tanfield to ensure your full project requirements are met and the right process followed to efficiently create the component you need.

Tolerance and surface finish requirements

Determining the tolerances your project needs will mostly be in relation to the function of what the component is going to have. In some instances, the metal-spun part won’t need to be the same thickness throughout, but it’s important to specify if your project requires a uniform thickness.

Expert metal spinners will have the knowledge and understanding of where to focus stress points during the process. Also, it is beneficial to know the surface finish your part needs to make sure it’s finished effectively to meet the standards and needs of the project.

Metal Spinning

Metal Spinning Bespoke Metal Spinning

Bespoke Metal Spinning Metal Polishing

Metal Polishing Machining

Machining Metal Pressing

Metal Pressing Metal Swaging

Metal Swaging Metal Fabrication & Welding

Metal Fabrication & Welding Precision Engineering

Precision Engineering Laser Cutting

Laser Cutting Inspection and Quality

Inspection and Quality Anodising, Electropolishing and Pickling & Passivating

Anodising, Electropolishing and Pickling & Passivating Agriculture

Agriculture Automotive

Automotive Air Movement

Air Movement Food Industry

Food Industry Marine

Marine Medical and Cryogenic

Medical and Cryogenic Playground

Playground Pressure Vessels

Pressure Vessels Renewable Energy

Renewable Energy Safety

Safety